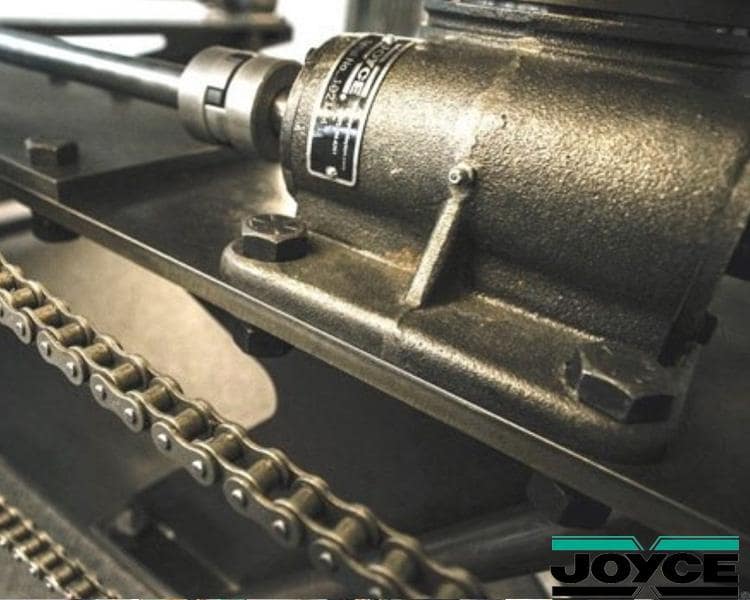

Joyce: Actuators, Screw Jacks and More!

Actuators, Jacks, and More!

Joyce Dayton is one of North America's premier manufacturers of mechanical and electric actuators, lifting systems, and screw jacks. Their extensive product line encompasses linear actuators, rotary actuators, and various other motion control solutions, all meticulously designed for precision and reliability. With a focus on durability and performance, Joyce Dayton's lifting systems feature screw jacks and electric cylinders capable of efficiently handling heavy loads across diverse industrial applications.

Resources

Download the Joyce Catalog to learn more about their range of screw jacks and actuators.

Joyce CatalogAbout Actuators

At Industrial Precision Services, we specialize in sourcing actuator products in various sizes and capacities for different applications. Actuators serve a ‘mission-critical’ role in many industrial applications and are typically made to order for your specific needs.

Industrial Machine Screw Actuators for Heavy-Duty Linear Motion

Machine Screw Actuators are engineered for precise, reliable linear motion in heavy industrial applications. Designed to lift, lower, push, or pull loads up to 250 tons, these actuators offer excellent positioning accuracy, uniform lifting speeds, and robust performance in demanding environments. With multiple configurations available—including upright and inverted units, translating or rotating lifting screws—they're a versatile solution for a wide range of industrial positioning needs.

These actuators are commonly used in material handling systems, assembly lines, automation cells, and other environments where controlled motion and heavy lifting are required. End options include top plate, plain, threaded, or clevis ends to suit your mounting and integration needs.

- Precision Acme Thread Design allows accurate positioning within thousandths of an inch.

- Self-Locking Mechanism ensures stability without external brakes in low-vibration conditions.

- Hardened Steel Gears enhance durability and operational efficiency.

- Synchronized Lifting is possible using multiple units thanks to matched gear sets.

- Rugged Construction using cast aluminum alloy (MA models) or ductile iron for safe, long-lasting performance.

Applications of Machine Screw Actuators

Machine screw actuators are ideal for applications requiring precise positioning and high static load capacity. Industries that benefit include:

- Manufacturing & automation

- Steel and metal processing

- Construction equipment positioning

- Testing machinery and loading systems

They are especially effective in setups where speed is not the priority but stability and precision are critical.

High-Efficiency Ball Screw Actuators for Speed and Precision

Ball Screw Actuators deliver high-speed, high-efficiency linear motion, making them ideal for dynamic industrial environments. With thrust capacities of up to 100 tons, these actuators use a low-friction ball screw and nut mechanism to minimize energy loss and reduce wear, enabling faster travel speeds and extended service life. Their design reduces power requirements, making them a cost-effective choice for continuous-duty applications.

Available in multiple configurations, ball screw actuators are a smart fit for high-cycle operations like packaging, press automation, and semiconductor handling systems.

- Designed for High-Speed Operation in continuous and automated processes.

- Low-Friction Ball Screw Design reduces horsepower requirements.

- Longer Life Span due to reduced mechanical wear and lower heat buildup.

- Integrated Bearings ensure smooth, consistent motion with reduced maintenance.

- Accurate Positioning with tight screw lead tolerances—ideal for synchronized multi-actuator systems.

When to Choose a Ball Screw Actuator

If your application demands higher speeds, continuous cycling, or energy efficiency, ball screw actuators are the ideal choice. They outperform machine screw models in dynamic applications where reduced friction and faster movement are needed.

Common use cases include:

- Automated manufacturing systems

- Conveyor systems and presses

- Medical imaging or scanning equipment

- High-speed pick-and-place robotics

Machine Screw vs. Ball Screw Actuators: What's the Difference?

Choosing between a machine screw actuator and a ball screw actuator depends on your specific application needs. While both serve to convert rotary motion into linear motion, their key differences lie in efficiency, speed, self-locking capabilities, and overall cost.

| Feature | Machine Screw Actuator | Ball Screw Actuator |

|---|---|---|

| Efficiency | Low (30-50%) | High (85-90%) |

| Speed | Slower | Faster |

| Self-Locking | Yes | No (requires brake or motor lock) |

| Maintenance | Minimal | Moderate |

| Cost | Lower | Higher |

Frequently Asked Questions

Can screw actuators be used outdoors?

Yes. Both machine screw and ball screw actuators can be specified with protective boots and corrosion-resistant finishes for outdoor use.

Do I need a brake with a machine screw actuator?

No. One of the primary advantages of machine screw actuators is their self-locking ability under static load in low-vibration environments.

Can I synchronize multiple actuators?

Yes. Precision gear design and consistent screw lead allow both machine screw and ball screw actuators to operate in tandem, using mechanical linkages or control systems.